품질과 실적

고객께서 우리의 기술을 안심하고 활용하실 수 있도록 과거의 실적을 JIS규격에 준한 WPS(Welding Procedure Specification)와 PQR(Procedure Qualification Record)로 기록하고 있습니다. 또한 풍부한 해외공사, 해외 기술지도 실적이 있으며, 국내외의 고객께 높은 신뢰를 받고 있습니다.

-

Class 2 pressure vessel tank

Material: SUS304

Size: Φ1200x1500L

-

Titanium transport tank

Material: TP340

Size: Φ1450 x 2800L

-

Titanium piping

Material: TTP340W

Size: 550A

-

Titanium monument

Material: TP340

Size: 1200x1200x1500H

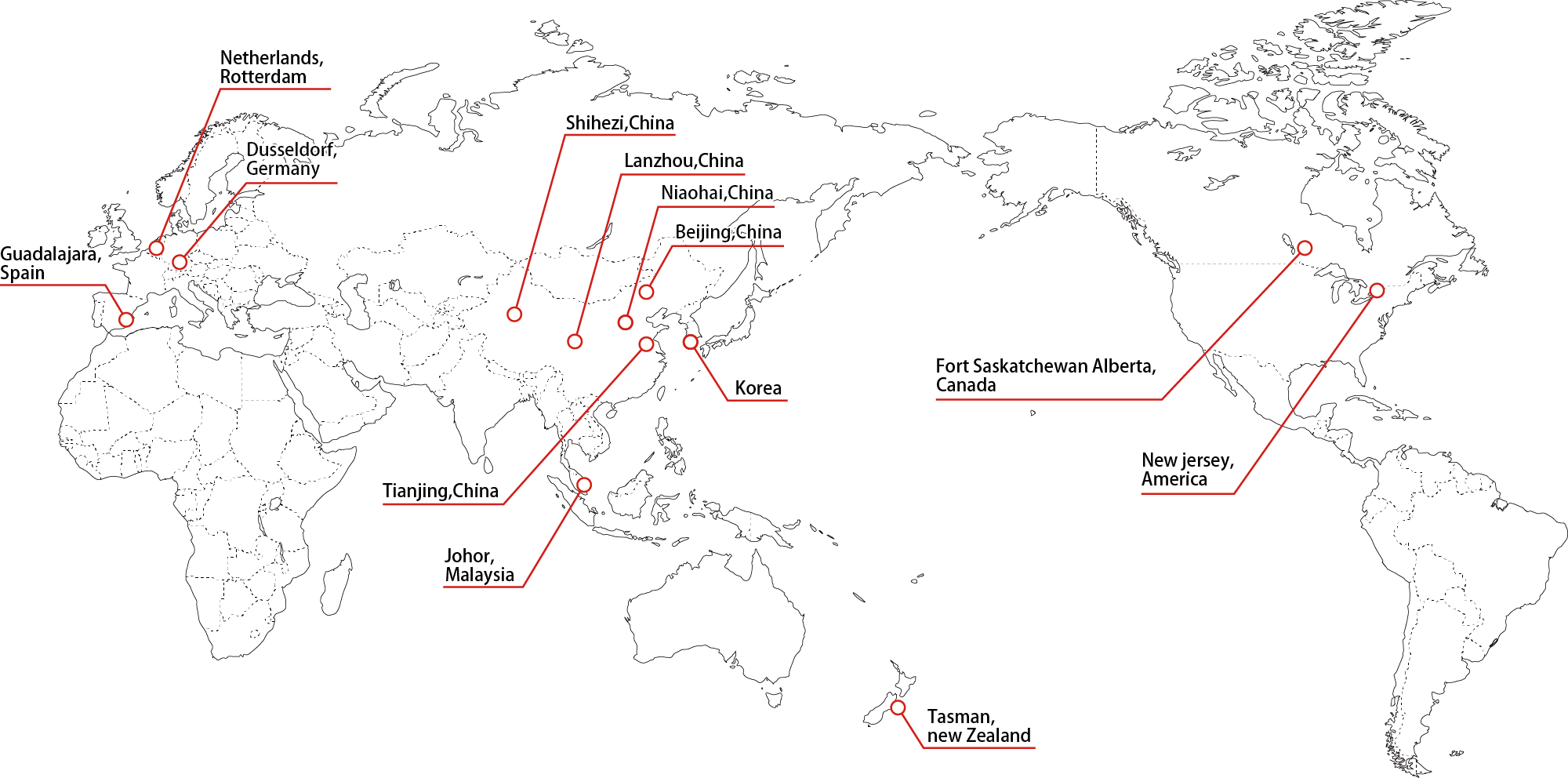

실적 세계지도

WPS&PQR LIST

| NO | Base Metal | Joints | Materials | Size(Thickness) | Machine Examination | Non Destructive Inspection | Other Inspection | ||||||

| Plate | Pipe | Pulling | Bending | Burst | PT | RT | Macro | Micro | Shock wave | ||||

| 1 | SUS310ELC | Joint fitting | ○ | – | t6 | ○ | ○ | – | – | – | – | – | – |

| 2 | TTP480 | Joint fitting | – | ○ | t5x40A | ○ | – | – | ○ | ○ | – | – | – |

| 3 | TTP480 | Joint fitting | – | ○ | t5x40A | – | ○ | – | ○ | ○ | – | – | – |

| 4 | TTP480 | Joint fitting | – | ○ | t12x125A | ○ | ○ | – | ○ | ○ | – | – | – |

| 5 | NAS254N | Joint fitting | ○ | – | t8 | ○ | ○ | – | ○ | – | – | – | – |

| 6 | TTP340 | Joint fitting | – | ○ | t8x150A | ○ | ○ | – | ○ | ○ | – | – | – |

| 7 | SUS304 | Joint fitting | – | ○ | t3x80A | ○ | ○ | – | ○ | ○ | – | – | – |

| 8 | TTP340 | Branch fitting | – | ○ | t3x200A | – | – | – | ○ | – | ○ | – | – |

| 9 | TTP340 | Branch fitting | – | ○ | t3x50A | – | – | – | ○ | – | ○ | – | – |

| 10 | TTP340 | Branch fitting | – | ○ | t3x25A | – | – | – | ○ | – | ○ | – | – |

| 11 | TP340 | Fillet fitting | ○ | – | 3.5(throat) | – | – | ○ | ○ | – | ○ | – | – |

| 12 | TP340 | Fillet fitting | ○ | – | 7(throat) | – | – | ○ | ○ | – | ○ | – | – |

| 13 | TP340 | Fillet fitting | ○ | – | 11(throat) | – | – | ○ | ○ | – | ○ | – | – |

| 14 | Ni201 | Branch fitting | – | ○ | t3x250A | – | – | – | ○ | – | ○ | – | – |

| 15 | Ni201 | Branch fitting | – | ○ | 50A | – | – | – | ○ | – | ○ | – | – |

| 16 | Ni201 | Branch fitting | – | ○ | sch40x25A3.5(throat) | – | – | – | ○ | – | ○ | – | – |

| 17 | Ni201 | Fillet fitting | ○ | – | 7(throat) | – | – | ○ | ○ | – | ○ | – | – |

| 18 | Ni201 | Fillet fitting | ○ | – | 11(throat) | – | – | ○ | ○ | – | ○ | – | – |

| 19 | Ni201 | Fillet fitting | ○ | – | t8 | – | – | ○ | ○ | – | ○ | – | – |

| 20 | HC-22 | Joint fitting | ○ | – | t8 | ○ | ○ | – | ○ | ○ | – | – | – |

| 21 | HC-276 | Joint fitting | ○ | – | t8 | ○ | ○ | – | ○ | ○ | – | – | – |

| 22 | HB-2 | Joint fitting | ○ | – | t8 | ○ | ○ | – | ○ | ○ | – | – | – |

| 23 | INCONEL600 | Joint fitting | ○ | – | t8 | ○ | ○ | – | ○ | ○ | – | – | – |

| 24 | INCLNEL625 | Joint fitting | ○ | – | t8 | ○ | ○ | – | ○ | ○ | – | – | – |

| 25 | NAS64N | Joint fitting | ○ | – | t8 | ○ | ○ | – | ○ | ○ | – | – | – |

| 26 | NAS185N(254SMO) | Joint fitting | ○ | – | t8 | ○ | ○ | – | ○ | ○ | – | – | – |

| 27 | INOCLOY800H | Joint fitting | ○ | – | t8 | ○ | ○ | – | ○ | ○ | – | – | – |

| 28 | INCOLOY825 | Joint fitting | ○ | – | t8 | ○ | ○ | – | ○ | ○ | – | – | – |

| 29 | ALLOY20Cb3 | Joint fitting | ○ | – | t8 | ○ | ○ | – | ○ | ○ | – | – | – |

| 30 | INCONEL601 | Joint fitting | ○ | – | t8 | ○ | ○ | – | ○ | ○ | – | – | – |

| 31 | MONEL400 | Joint fitting | ○ | – | t8 | ○ | ○ | – | ○ | ○ | – | – | – |

| 32 | MONEL400/SUS304 | Joint fitting | ○ | – | t8 | ○ | ○ | – | ○ | ○ | – | – | – |

| 33 | C1100P/SS400 | Joint fitting | ○ | – | t9 | ○ | ○ | – | ○ | ○ | – | – | – |

| 34 | SUS304/SS400 | Joint fitting | ○ | – | t9 | ○ | ○ | – | ○ | ○ | – | – | – |

| 35 | SUS304/SUS304 | Joint fitting | ○ | – | t10 | ○ | ○ | – | ○ | ○ | – | – | – |

Qualification

In everything we do, we always aim to vigorously pursue the creation of new value that exceeds customer expectations, the establishment of a corporate culture that encourages pride and confidence in our work and the improvement of our world-class technology in order to become a company that benefits society.

| Type of qualification | number of holders |

| Nomal Boiler Welder (Japan Boiler Association certificate) | 1 |

| Special Boiler Welder (Japan Boiler Association certificate) | 1 |

| JIS(Japanese Industrial Standards )TN-F (Stainless steel TIG Welding) | 28 |

| JIS(Japanese Industrial Standards )TN-V (Stainless steel TIG Welding) | 2 |

| JIS(Japanese Industrial Standards ) TN-P (Stainless steel pipe TIG Welding) | 8 |

| JIS(Japanese Industrial Standards )RT-F (Titanium Welding) | 18 |

| JIS(Japanese Industrial Standards )RT-P (Titanium Welding) | 5 |

| Nondestructive Testing Engineer (Solvent removal penetrant inspection level 2) | 4 |