Quality and Experience

We provide WPS (Welding Procedure Specifications) and PQR (Procedure Qualification Records) on our past achievements in accordance with JIS so that our customers can use our technology with confidence. We have a solid track record in work and technical guidance in other countries as well and have earned great trust among customers in Japan and around the world.

-

Class 2 pressure vessel tank

Material: SUS304

Size: Φ1200x1500L

-

Titanium transport tank

Material: TP340

Size: Φ1450 x 2800L

-

Titanium piping

Material: TTP340W

Size: 550A

-

Titanium monument

Material: TP340

Size: 1200x1200x1500H

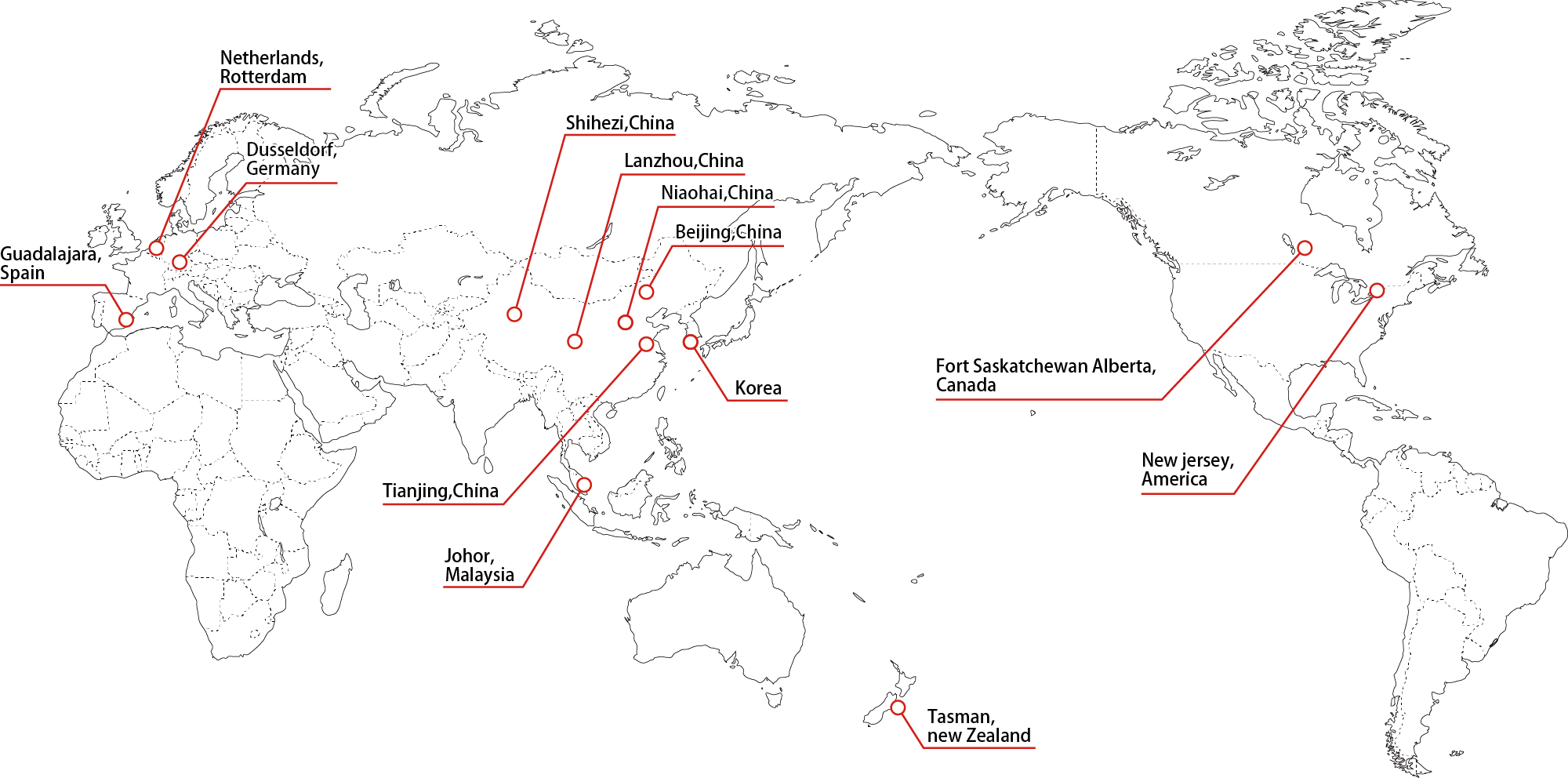

Actual world map

WPS&PQR LIST

| NO | Base Metal | Joints | Materials | Size(Thickness) | Machine Examination | Non Destructive Inspection | Other Inspection | ||||||

| Plate | Pipe | Pulling | Bending | Burst | PT | RT | Macro | Micro | Shock wave | ||||

| 1 | SUS310ELC | Joint fitting | ○ | – | t6 | ○ | ○ | – | – | – | – | – | – |

| 2 | TTP480 | Joint fitting | – | ○ | t5x40A | ○ | – | – | ○ | ○ | – | – | – |

| 3 | TTP480 | Joint fitting | – | ○ | t5x40A | – | ○ | – | ○ | ○ | – | – | – |

| 4 | TTP480 | Joint fitting | – | ○ | t12x125A | ○ | ○ | – | ○ | ○ | – | – | – |

| 5 | NAS254N | Joint fitting | ○ | – | t8 | ○ | ○ | – | ○ | – | – | – | – |

| 6 | TTP340 | Joint fitting | – | ○ | t8x150A | ○ | ○ | – | ○ | ○ | – | – | – |

| 7 | SUS304 | Joint fitting | – | ○ | t3x80A | ○ | ○ | – | ○ | ○ | – | – | – |

| 8 | TTP340 | Branch fitting | – | ○ | t3x200A | – | – | – | ○ | – | ○ | – | – |

| 9 | TTP340 | Branch fitting | – | ○ | t3x50A | – | – | – | ○ | – | ○ | – | – |

| 10 | TTP340 | Branch fitting | – | ○ | t3x25A | – | – | – | ○ | – | ○ | – | – |

| 11 | TP340 | Fillet fitting | ○ | – | 3.5(throat) | – | – | ○ | ○ | – | ○ | – | – |

| 12 | TP340 | Fillet fitting | ○ | – | 7(throat) | – | – | ○ | ○ | – | ○ | – | – |

| 13 | TP340 | Fillet fitting | ○ | – | 11(throat) | – | – | ○ | ○ | – | ○ | – | – |

| 14 | Ni201 | Branch fitting | – | ○ | t3x250A | – | – | – | ○ | – | ○ | – | – |

| 15 | Ni201 | Branch fitting | – | ○ | 50A | – | – | – | ○ | – | ○ | – | – |

| 16 | Ni201 | Branch fitting | – | ○ | sch40x25A3.5(throat) | – | – | – | ○ | – | ○ | – | – |

| 17 | Ni201 | Fillet fitting | ○ | – | 7(throat) | – | – | ○ | ○ | – | ○ | – | – |

| 18 | Ni201 | Fillet fitting | ○ | – | 11(throat) | – | – | ○ | ○ | – | ○ | – | – |

| 19 | Ni201 | Fillet fitting | ○ | – | t8 | – | – | ○ | ○ | – | ○ | – | – |

| 20 | HC-22 | Joint fitting | ○ | – | t8 | ○ | ○ | – | ○ | ○ | – | – | – |

| 21 | HC-276 | Joint fitting | ○ | – | t8 | ○ | ○ | – | ○ | ○ | – | – | – |

| 22 | HB-2 | Joint fitting | ○ | – | t8 | ○ | ○ | – | ○ | ○ | – | – | – |

| 23 | INCONEL600 | Joint fitting | ○ | – | t8 | ○ | ○ | – | ○ | ○ | – | – | – |

| 24 | INCLNEL625 | Joint fitting | ○ | – | t8 | ○ | ○ | – | ○ | ○ | – | – | – |

| 25 | NAS64N | Joint fitting | ○ | – | t8 | ○ | ○ | – | ○ | ○ | – | – | – |

| 26 | NAS185N(254SMO) | Joint fitting | ○ | – | t8 | ○ | ○ | – | ○ | ○ | – | – | – |

| 27 | INOCLOY800H | Joint fitting | ○ | – | t8 | ○ | ○ | – | ○ | ○ | – | – | – |

| 28 | INCOLOY825 | Joint fitting | ○ | – | t8 | ○ | ○ | – | ○ | ○ | – | – | – |

| 29 | ALLOY20Cb3 | Joint fitting | ○ | – | t8 | ○ | ○ | – | ○ | ○ | – | – | – |

| 30 | INCONEL601 | Joint fitting | ○ | – | t8 | ○ | ○ | – | ○ | ○ | – | – | – |

| 31 | MONEL400 | Joint fitting | ○ | – | t8 | ○ | ○ | – | ○ | ○ | – | – | – |

| 32 | MONEL400/SUS304 | Joint fitting | ○ | – | t8 | ○ | ○ | – | ○ | ○ | – | – | – |

| 33 | C1100P/SS400 | Joint fitting | ○ | – | t9 | ○ | ○ | – | ○ | ○ | – | – | – |

| 34 | SUS304/SS400 | Joint fitting | ○ | – | t9 | ○ | ○ | – | ○ | ○ | – | – | – |

| 35 | SUS304/SUS304 | Joint fitting | ○ | – | t10 | ○ | ○ | – | ○ | ○ | – | – | – |

Qualification

In everything we do, we always aim to vigorously pursue the creation of new value that exceeds customer expectations, the establishment of a corporate culture that encourages pride and confidence in our work and the improvement of our world-class technology in order to become a company that benefits society.

| Type of qualification | number of holders |

| Nomal Boiler Welder (Japan Boiler Association certificate) | 1 |

| Special Boiler Welder (Japan Boiler Association certificate) | 1 |

| JIS(Japanese Industrial Standards )TN-F (Stainless steel TIG Welding) | 28 |

| JIS(Japanese Industrial Standards )TN-V (Stainless steel TIG Welding) | 2 |

| JIS(Japanese Industrial Standards ) TN-P (Stainless steel pipe TIG Welding) | 8 |

| JIS(Japanese Industrial Standards )RT-F (Titanium Welding) | 18 |

| JIS(Japanese Industrial Standards )RT-P (Titanium Welding) | 5 |

| Nondestructive Testing Engineer (Solvent removal penetrant inspection level 2) | 4 |